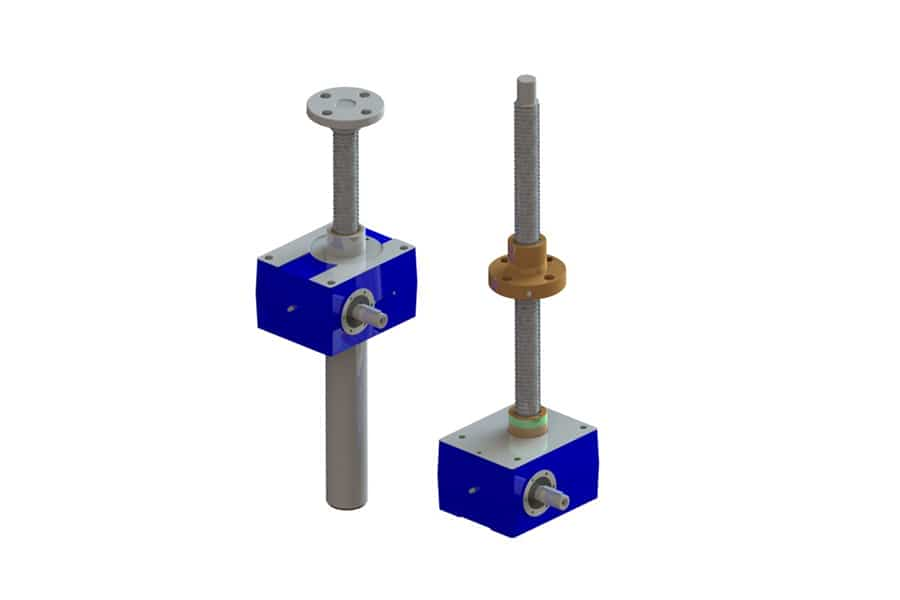

Screw Jacks: The Powerful Partners in Steel and Concrete Construction Assembly

admin

- 0

Steel and concrete construction projects are marvels of modern engineering, requiring a combination of precision and brute force. Screw jacks play a crucial role in this process, acting as powerful and versatile tools for efficient and safe assembly. This article explores the various applications of screw jacks in steel and concrete construction.

Lifting Heavy Elements with Confidence

Table of Contents

Toggle- Steel Beam Erection: Screw jacks are instrumental in lifting and precisely positioning heavy steel beams during erection. Their controlled lifting capabilities ensure safe and efficient placement of these critical structural elements.

- Precast Concrete Panel Installation: Similar to steel beams, screw jacks assist in maneuvering and installing prefabricated concrete panels. Their ability to handle substantial weight allows for accurate positioning of these components, accelerating the construction process.

- Formwork Support and Adjustment: Screw jacks are extensively used for supporting and adjusting formwork systems utilized in concrete pouring. They provide the necessary lifting power and precise control to ensure proper formwork alignment and stability throughout the concrete placement process.

Precise Positioning and Secure Clamping

- Column Alignment and Adjustment: Screw jacks can be used to precisely align and adjust prefabricated concrete columns, ensuring proper verticality and load distribution in the final structure.

- Shoring and Scaffolding Support: Screw jacks provide adjustable support for shoring and scaffolding systems commonly used in construction. This allows for safe access and work platforms at various heights throughout the construction phase.

- Expansion Joint Control: Screw jacks play a role in controlling the expansion and contraction of joints in concrete structures. Their controlled pushing or pulling force allows for precise adjustment of these joints, mitigating potential cracking and ensuring structural integrity.

For more information on screw jack design and material selection, you can visit MechJacks https://mechjacks.com/en/. MechJacks is a leading manufacturer of high-quality screw jacks, offering a wide range of options to suit various industrial applications.

Advantages of Using Screw Jacks in Steel and Concrete Construction

- Versatility: Screw jacks come in a variety of sizes and capacities, making them suitable for a wide range of lifting, pushing, and positioning tasks on the construction site.

- Precise Control: The mechanical advantage provided by screw jacks allows for fine-tuned adjustments, crucial for accurate placement of structural elements.

- Safety: Screw jacks offer a controlled and predictable lifting or pushing force compared to hydraulic systems. This reduces the risk of accidents associated with handling heavy components.

- Durability: Built to withstand the harsh conditions of a construction site, screw jacks provide reliable performance and long service life.

- Ease of Use: Screw jacks are generally easy to operate and require minimal maintenance, making them a user-friendly tool for construction crews.

Choosing the Right Screw Jack for the Job

When selecting screw jacks for construction applications, consider these key factors:

- Load Capacity: Choose a screw jack with a capacity exceeding the weight of the element you need to lift or position.

- Lifting Height: Ensure the screw jack has sufficient travel distance to achieve the desired lifting height.

- Duty Cycle: Match the duty cycle of the screw jack to the frequency and duration of use on the construction site.

- Environmental Factors: Consider weatherproofing or corrosion-resistant materials if the jacks will be exposed to harsh outdoor conditions.

Conclusion:

Screw jacks are more than just lifting tools; they are vital partners in ensuring efficient, precise, and safe assembly in steel and concrete construction projects. Their versatility, power, and ease of use make them a valuable asset for construction professionals, contributing to successful project completion.