Polyethylene Foam Types According to Usage Areas

admin

- 0

Polyethylene foam is a versatile material that finds applications in a wide range of industries. Its unique properties make it suitable for various usage areas, from cushioning and packaging to insulation and construction. In this article, we will explore the different types of polyethylene foam and how they are utilized in different industries.

Cushioning and Packaging:

Polyethylene foam is highly sought after for cushioning and packaging purposes. Its exceptional shock absorption capabilities make it ideal for protecting fragile items during transportation. Whether it’s delicate electronics, glassware, or furniture, polyethylene foam provides a cushioning effect that prevents damage caused by impacts or vibrations. Additionally, its lightweight nature ensures that the packaging remains lightweight, reducing shipping costs.

Insulation and Construction:

In the field of insulation and construction, polyethylene foam plays a crucial role. Its thermal insulation properties help maintain desired temperatures in buildings, reducing energy consumption and costs. Moreover, polyethylene foam acts as an effective soundproofing material, minimizing noise transfer between different areas. Its moisture resistance properties make it suitable for applications such as roof insulation, preventing water damage and mold growth.

Whether it’s protecting delicate items during shipping or providing insulation in buildings, polyethylene foam proves to be a reliable and versatile material. Its various types cater to specific usage areas, ensuring optimum performance in different industries. From cushioning and packaging to insulation and construction, polyethylene foam continues to be a preferred choice for professionals seeking reliable and efficient solutions.

Cushioning and Packaging

Polyethylene foam is widely recognized for its exceptional shock absorption and protective properties, making it an ideal material for cushioning and packaging applications. Whether it’s fragile electronic equipment, delicate glassware, or valuable artwork, polyethylene foam provides a reliable solution for protecting these items during transportation and storage.

One of the key advantages of polyethylene foam is its ability to absorb and distribute impact energy. When an object is dropped or experiences a sudden impact, the foam compresses and disperses the force, minimizing the risk of damage. This makes it an excellent choice for packaging delicate items that are prone to breakage.

Furthermore, polyethylene foam offers excellent cushioning properties, ensuring that even the most fragile and sensitive items remain secure and protected. Its closed-cell structure provides a barrier against moisture, dust, and other contaminants, preventing any potential damage or corrosion during transit.

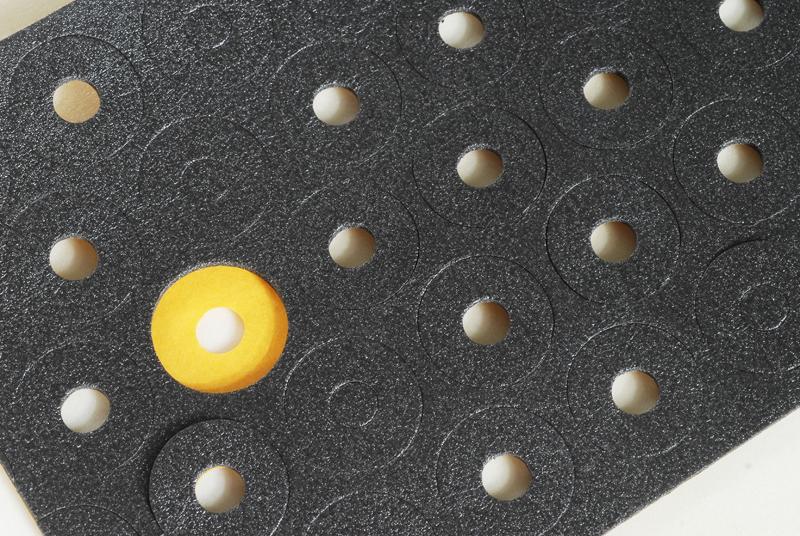

In addition to its protective qualities, polyethylene foam is lightweight and flexible, making it easy to handle and customize for specific packaging needs. It can be easily cut, shaped, and molded to fit the contours of the product, providing a snug and secure fit. This versatility allows for efficient use of space and reduces the need for excess packaging materials.

Overall, polyethylene foam is a reliable and cost-effective solution for cushioning and packaging applications. Its shock absorption, protective properties, and customization options make it an indispensable material for various industries, including electronics, automotive, healthcare, and e-commerce.

Insulation and Construction

Polyethylene foam is a versatile material that finds extensive use in insulation and construction applications. Its unique properties make it an ideal choice for various purposes in these industries.

One of the key benefits of polyethylene foam in insulation is its excellent thermal insulation capabilities. It acts as a barrier against heat transfer, helping to maintain a comfortable and energy-efficient environment. Whether it’s insulating walls, roofs, or pipes, polyethylene foam provides an effective solution for reducing heat loss or gain.

In addition to thermal insulation, polyethylene foam also offers soundproofing properties. Its closed-cell structure absorbs sound waves, reducing noise transmission and creating a quieter indoor environment. This makes it a popular choice for soundproofing walls, floors, and ceilings in buildings, as well as in acoustic panels and insulation for recording studios or theaters.

Furthermore, polyethylene foam exhibits excellent moisture resistance, making it suitable for applications where water or moisture is a concern. Its closed-cell structure prevents water absorption, ensuring long-term durability and preventing the growth of mold or mildew. This makes it an ideal choice for insulating basements, crawl spaces, and other areas prone to moisture.

In summary, polyethylene foam is a versatile material that offers thermal insulation, soundproofing, and moisture resistance in insulation and construction applications. Its ability to provide these benefits makes it a valuable choice for various industries, ensuring energy efficiency, comfort, and durability.

As we come to the end of our article, we strongly recommend that you review the following pages: